CARBON

FOOTPRINT

REDUCING OUR CARBON FOOTPRINT

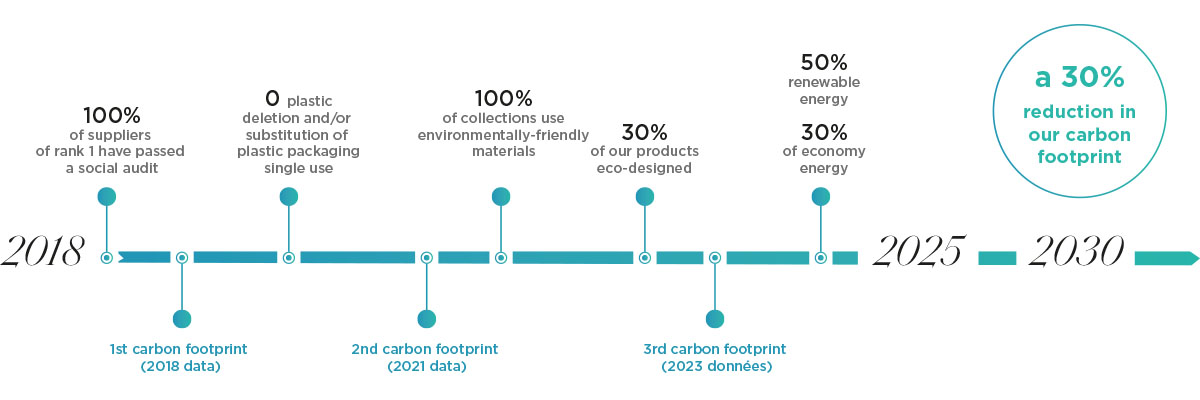

After 2018 and 2021, the Group conducted its third carbon footprint assessment in 2023. We have reduced our CO2 emissions in absolute terms by 19% since 2018.

We have chosen to act on our two main areas of progress:

- Raw materials which represents 53% of our carbon emissions, through the strengthening of our eco-design approach.

- The control of our energy consumption, already reduced by 49% across our entire network of stores and buildings (headquarters, logistics, factory, etc.).

- Manufacturing, which represents 19% of carbon emissions, through the implementation of environmental audits.

Our innovative actions

THE ERAM GROUP HAS DEFINIED A COMMON FOUNDATION FOR ITS ECO-RESPONSIBLE OFFER

Since 2021, we have defined a common foundation for our responsible offer and we are rolling it out across all our brands thanks to our teams of experts.

With the support of Alliance du commerce and Deloitte Développement Durable, all our supply teams are trained in the ecodesign approach. They are supported to better understand the transformation challenges of our business sector and are trained in the new tools of their evolving professions.

BUTTERFLY, OUR ENVIRONMENTAL FOOTPRINT MEASUREMENT TOOL

To comply with regulations on environmental labeling (equivalent to the french “Nutri-Score” for textiles), we decided to develop our own measurement tool, “Butterfly”. The goal? To manage the environmental data of our products (textiles or footwear) and simplify the data collection process across the entire value chain (suppliers, purchasing department, and customers) through a single database.

This software allows our teams to:

- Track production stages,

- Accurately measure the carbon footprint of products,

- Communicate the environmental characteristics of our products to customers.

Butterfly allows us to measure our environmental impact throughout the entire product lifecycle, from the origin of the material to the end of life, to achieve our goal of reducing GHG emissions.

THE ERAM GROUP PREPARES FOR THE CHALLENGES OF THE CSRD

The European Union has recently introduced a new methodology for the publication of corporate data on environmental, social, and governance matters, called the Corporate Sustainability Reporting Directive (CSRD).

This directive requires European companies to disclose non-financial information about their sustainability performance, adhering to standardized norms to facilitate comparisons between companies.

Although the implementation of this directive is scheduled for 2026, the Eram Group has chosen to prepare now. Initiatives have been launched to train the relevant departments within the Group and its various brands. To date, more than 70 employees have participated in training sessions and collaborative workshops on the impact of our activities.

REDUCTION OF OUR ENERGY CONSUMPTION

Since 2015, the Group has reduced its energy consumption by 49% across its entire network of stores and buildings (headquarters, logistics, factory, etc.).

Stores, which represent more than 70% of the total energy consumption, have been given special attention through significant investments and extensive team awareness. Thanks to a series of actions carried out in stores, at the headquarters, in warehouses, and factories (switching to LED lighting in stores and warehouses, less energy-intensive store concepts, flex-office at the headquarters to reduce heated and lit areas every Friday, etc.), the collective effort has once again proven its effectiveness.

THE ERAM GROUP, A KEY PLAYER IN GREEN ENERGY

We have signed off the creation of the company Mauges BioGNV, in partnership with carrier companies, Jolival and Pohu, two farming collectives and the Mauges Energie local authority, to launch the first Biogas station in the Mauges region.

Biogas is a virtuous alternative fuel that emits 82% less CO2 than conventional fuels, 95% less fine particles and creates 50% less noise pollution for the vehicles that use it. It is obtained through the transformation of agricultural waste generated locally (Mauges). It has been used by the carrier Jolival since the end of April 2022 to supply 26 Gémo shops in western France (59% of deliveries in the region).

Through this commitment, we aim to reduce our dependence on fossil fuels and control our value chain.

OKSIGEN SUPPORTS THE ERAM GROUP WITH ITS ENERGY MANAGMENT

Since 2020 Oksigen, a subsidiary of the Eram Group, has been supporting us. As a consulting company dedicated to helping businesses reduce their environmental footprint and accelerate their energy transition, its services are based on three pillars:

- Driving a low-carbon strategy,

- Improving energy efficiency,

- Optimizing energy costs.